dental vacuum pump

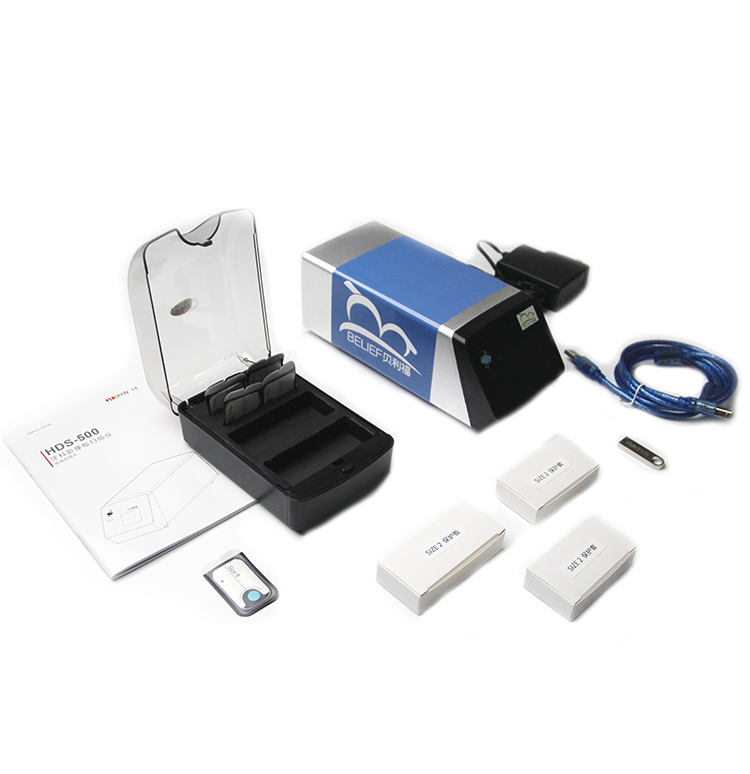

A dental vacuum pump serves as a crucial component in modern dental practices, providing essential suction power for various dental procedures and maintaining a clean, safe operating environment. This specialized equipment generates the necessary vacuum pressure to remove fluids, debris, and aerosols from the patient's mouth during dental treatments. Operating through advanced motor technology, these pumps create consistent and reliable suction power while maintaining quiet operation. The system typically comprises a powerful motor unit, filtration system, and moisture separation mechanism, working together to ensure optimal performance. These pumps are designed to handle both wet and dry vacuum requirements, making them versatile for different dental applications. The integrated filtration system prevents contamination and protects the internal components from debris, extending the equipment's lifespan. Modern dental vacuum pumps incorporate smart features such as automatic moisture detection, variable speed control, and energy-efficient operation modes. They are engineered to meet strict medical standards and provide the necessary suction power for multiple operatories simultaneously, making them ideal for both small practices and larger dental facilities.