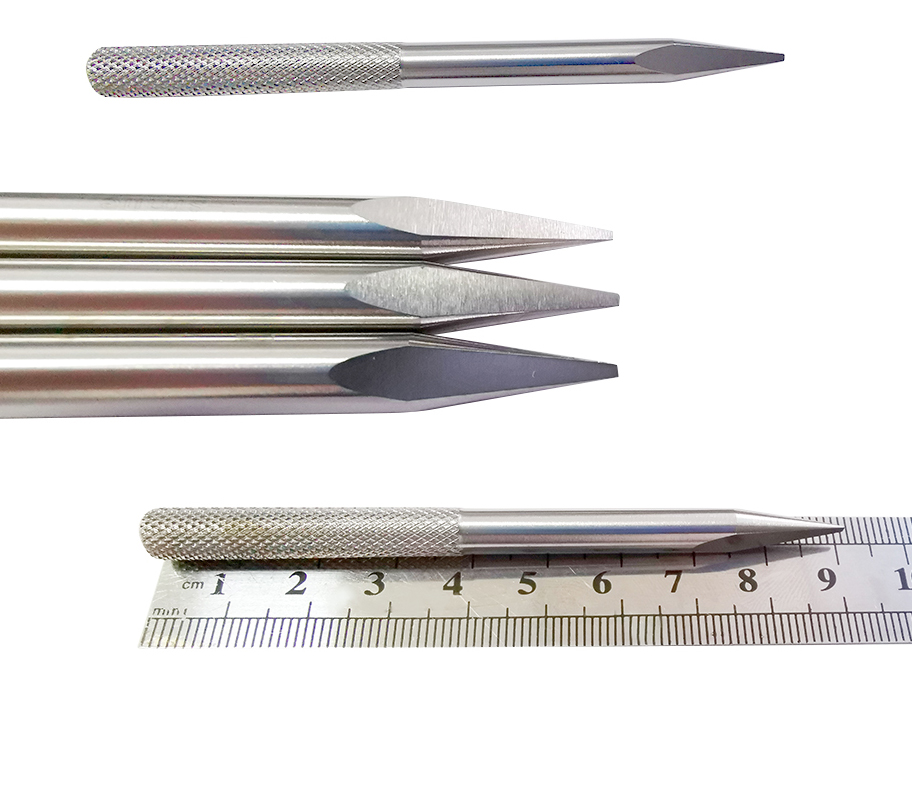

ملفات إبرة صغيرة

تُعد أدوات الصقل الصغيرة أدوات يدوية دقيقة مصممة لأعمال التشغيل الدقيقة على المعادن، وصناعة المجوهرات، وأعمال التشطيب المعقدة. وتتميز هذه الأدوات بأسنان دقيقة وتصميمات رفيعة، وعادة ما تتراوح أطوالها بين 3 إلى 8 بوصات، مما يجعلها مثالية للوصول إلى المساحات الضيقة وإجراء عمليات إزالة دقيقة للمواد. تأتي كل أداة صقل بأشكال مقطعية متنوعة، مثل الدائري والمستطيل والمثلث والنمط المسطح، مما يمكّن الحرفيين من العمل على أسطح ذات أشكال مختلفة وزوايا متنوعة. تُصنع هذه الأدوات من فولاذ عالي الكربون أو من مواد مطلية بالألماس، مما يضمن متانتها وأداؤها المستقر عبر مختلف الاستخدامات. تسمح الأنماط الدقيقة للأسنان الموجودة على هذه الأدوات بتحكم دقيق في إزالة المواد، مما يجعلها ضرورية لأداء مهام مثل إزالة الحواف الخشنة، وتجليس الحواف، وصنع التفاصيل المعقدة في الأعمال المعدنية. وهي ذات قيمة خاصة في صناعة الساعات وصناعة النماذج والنقشات الفنية الدقيقة، حيث تكون الدقة والتحكم لها الأولوية. كما توفر المقابض المريحة قبضة ممتازة وتحكمًا دقيقًا، مما يقلل من إرهاق اليد أثناء الاستخدام الطويل مع الحفاظ على الدقة في الأعمال التفصيلية. وتُستخدم هذه الأدوات أيضًا بشكل واسع في تصنيع مكونات كهربائية وإلكترونية لعمليات التركيب والتشطيب الدقيقة.