Understanding Modern Dental Sterilization Protocols

The meticulous sterilization of dental instruments stands as a cornerstone of safe and effective dental practice. Modern dental offices employ sophisticated sterilization protocols that ensure every tool that enters a patient's mouth is completely free from harmful microorganisms. This comprehensive process involves multiple stages of cleaning, disinfection, and sterilization, all designed to maintain the highest standards of patient safety while preserving the integrity of these precision instruments.

Dental instruments undergo rigorous processing after each use, following strict guidelines established by healthcare regulatory bodies. These protocols have evolved significantly over the decades, incorporating advanced technologies and evidence-based practices to create a foolproof system of instrument sterilization. Understanding these procedures not only demonstrates the dedication of dental professionals to patient safety but also highlights the complexity of modern dental care.

The Complete Sterilization Process

Initial Cleaning and Decontamination

The journey of dental instruments through the sterilization process begins immediately after use. Staff members wearing appropriate protective equipment carefully collect used instruments and transport them to the designated sterilization area. Here, the instruments undergo initial cleaning to remove visible debris, blood, and tissue. This step often involves ultrasonic cleaning devices that use high-frequency sound waves to dislodge contamination from even the smallest crevices in the instruments.

Following the ultrasonic bath, dental instruments are thoroughly rinsed with purified water to remove any remaining debris and cleaning solution. This step is crucial as it prevents any chemical residue from interfering with the subsequent sterilization process. The instruments are then carefully dried to prevent water spots and potential corrosion.

Packaging and Preparation

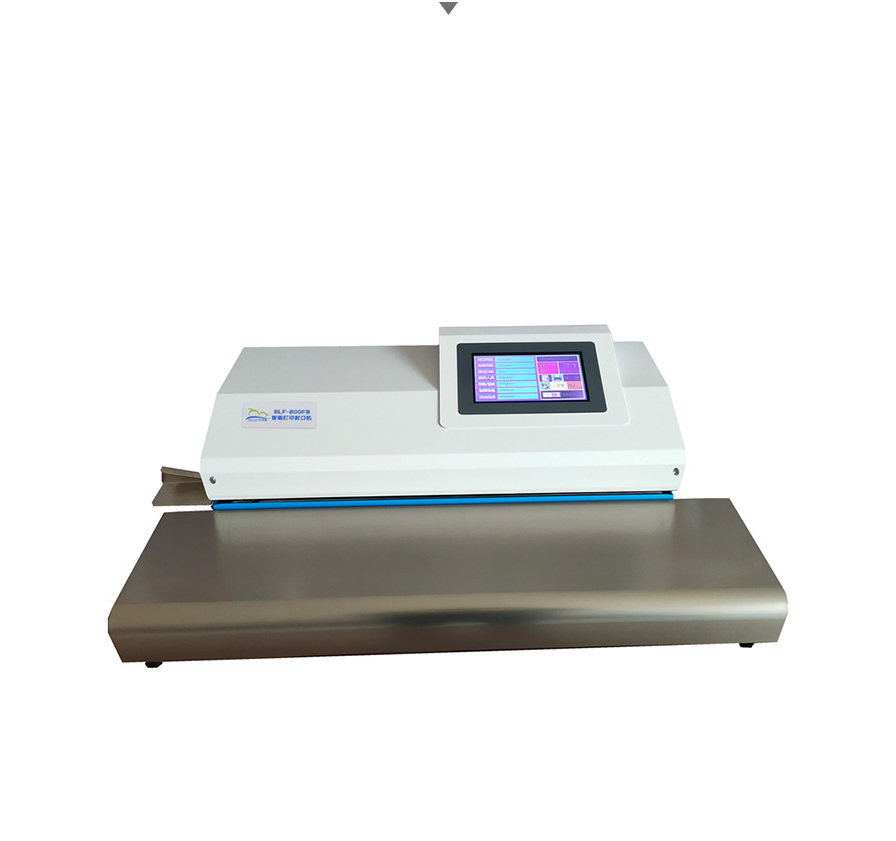

Once cleaned and dried, dental instruments are meticulously inspected for any damage or wear. Each instrument is carefully sorted and organized into appropriate sterilization packages or cassettes. These packages are designed with special materials that allow steam penetration while maintaining sterility after processing. Each package is sealed and labeled with indicators that change color during sterilization, providing visual confirmation of proper processing.

The packaging process also includes the placement of internal chemical indicators that provide additional verification of sterilization conditions. These sophisticated monitoring systems ensure that every instrument package receives adequate exposure to sterilizing conditions throughout the entire cycle.

Advanced Sterilization Technologies

Steam Autoclave Processing

The primary method for sterilizing dental instruments is steam sterilization using an autoclave. This process exposes the packaged instruments to pressurized steam at temperatures typically reaching 121-134°C (250-273°F). The combination of high temperature, pressure, and moisture effectively eliminates all forms of microorganisms, including bacteria, viruses, fungi, and spores.

Modern autoclaves feature sophisticated control systems that monitor and document every aspect of the sterilization cycle. These parameters include temperature, pressure, and exposure time, ensuring that each batch of instruments meets strict sterilization standards. The entire process typically takes between 30-60 minutes, depending on the specific cycle parameters and load size.

Alternative Sterilization Methods

While steam autoclaves remain the gold standard, some dental practices may employ additional or alternative sterilization methods for specific instruments. Chemical vapor sterilization, dry heat sterilization, and low-temperature hydrogen peroxide gas plasma systems offer specialized solutions for heat-sensitive or delicate dental instruments.

These alternative methods must meet the same rigorous standards for sterilization efficacy while preserving the integrity and functionality of the instruments. Each method has specific advantages and applications, allowing dental practices to choose the most appropriate sterilization approach for their particular needs.

Quality Assurance and Monitoring

Sterilization Verification Systems

Dental practices implement comprehensive monitoring systems to verify the effectiveness of their sterilization procedures. These include mechanical monitors that track cycle parameters, chemical indicators that change color when exposed to specific conditions, and biological indicators containing bacterial spores that confirm complete sterilization.

Regular testing with biological indicators provides the highest level of sterilization verification. These tests use highly resistant bacterial spores as a challenge to the sterilization process. Successfully eliminating these test organisms confirms that the sterilization system is functioning properly and capable of destroying all potential pathogens.

Documentation and Tracking

Modern dental practices maintain detailed records of their sterilization procedures, including cycle parameters, test results, and maintenance records. This documentation serves multiple purposes, from ensuring regulatory compliance to providing quality assurance and risk management. Advanced tracking systems may use barcodes or RFID technology to monitor individual instrument packages throughout their lifecycle.

Regular audits of sterilization procedures and documentation help maintain high standards and identify any areas for improvement. This systematic approach to quality assurance protects both patients and practitioners while demonstrating commitment to excellence in dental care.

Frequently Asked Questions

How long does the complete sterilization process take for dental instruments?

The entire process, from initial cleaning to final sterilization, typically takes 1-2 hours. This includes approximately 30 minutes for cleaning and preparation, and 30-60 minutes for the actual sterilization cycle. However, many dental practices maintain multiple sets of instruments to ensure continuous availability throughout the day.

Are all dental instruments sterilized the same way?

While most dental instruments undergo steam sterilization in an autoclave, some specialized or delicate instruments may require alternative methods. The specific sterilization approach depends on the instrument's materials, design, and manufacturer recommendations. All methods must meet strict regulatory standards for effectiveness.

How do patients know their dental instruments are properly sterilized?

Dental practices use visible indicators on instrument packages that change color when properly sterilized. Additionally, they maintain detailed sterilization records and undergo regular inspections. Patients can always ask to see their practice's sterilization protocols and certification records for peace of mind.