The Evolution of Modern Dental Instrument Materials

The landscape of dental instruments has transformed dramatically over the past century, with material science playing a pivotal role in shaping the tools dentists use today. Modern dental instruments represent the perfect fusion of durability, precision, and biocompatibility - qualities that are essential for delivering optimal patient care.

From basic examination tools to complex surgical implements, dental instruments face constant exposure to sterilization processes, chemicals, and mechanical stress. The materials used in their construction must therefore meet exceptionally high standards of performance and longevity.

Premium Metals in Dental Instrument Manufacturing

Stainless Steel: The Gold Standard

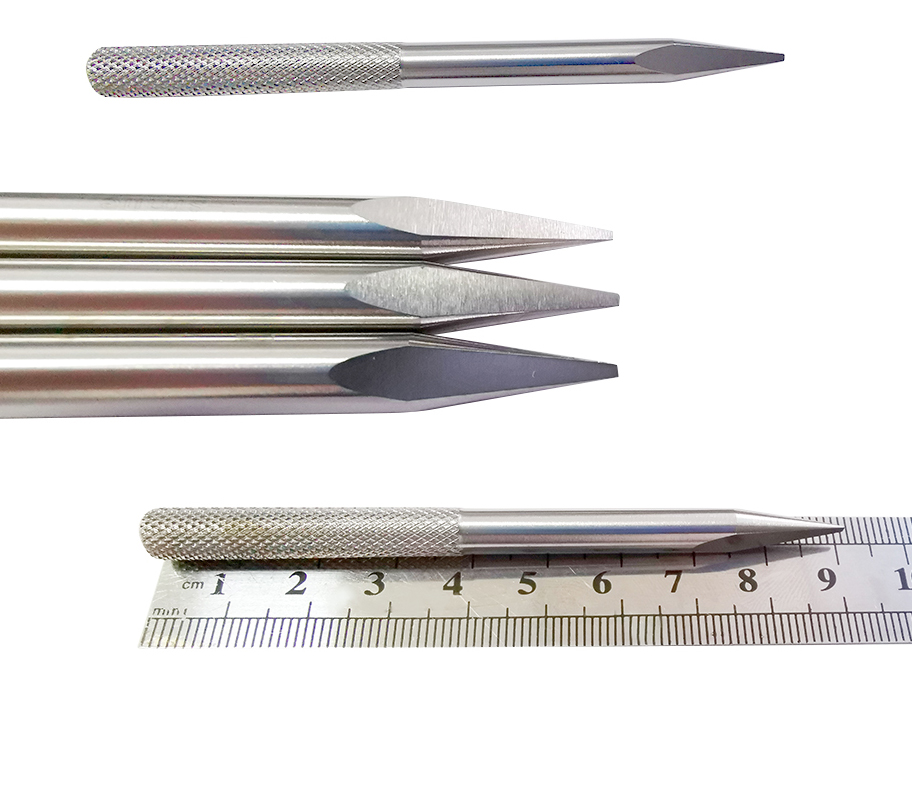

Stainless steel remains the most widely used material for dental instruments, particularly surgical-grade 420 and 440A varieties. These specialized alloys offer superior corrosion resistance, excellent edge retention, and remarkable durability. The high chromium content creates a protective oxide layer, while carbon provides the necessary hardness for cutting and scraping functions.

Modern dental instruments crafted from surgical stainless steel can withstand thousands of sterilization cycles without degrading, making them highly cost-effective over their lifetime. The material's ability to maintain structural integrity under repeated stress makes it ideal for instruments like scalers, explorers, and forceps.

Titanium and Its Alloys

Titanium has emerged as a premium choice for specialized dental instruments, particularly in microsurgical applications. Its exceptional strength-to-weight ratio and biocompatibility make it perfect for delicate procedures. Titanium dental instruments offer superior tactile sensitivity while being approximately 45% lighter than their stainless steel counterparts.

Additionally, titanium's natural resistance to corrosion and ability to withstand high temperatures make it ideal for instruments that require frequent sterilization. The material's non-magnetic properties also make it compatible with modern diagnostic equipment.

Advanced Composites and Hybrid Materials

Carbon Fiber Reinforced Polymers

The integration of carbon fiber reinforced polymers (CFRP) represents a significant advancement in dental instrument design. These materials combine impressive strength with exceptional lightness, reducing hand fatigue during lengthy procedures. CFRP dental instruments also offer superior vibration dampening properties, enhancing precision during microsurgical procedures.

While initially more expensive than traditional materials, CFRP instruments often prove more economical in the long run due to their extended lifespan and resistance to wear. Their non-conductive nature also makes them particularly suitable for procedures involving electronic dental equipment.

Ceramic-Based Composites

Ceramic composites have found their niche in specialized dental instruments, particularly those requiring exceptional hardness and wear resistance. These materials excel in applications where traditional metals might show signs of wear, such as in ultrasonic scaling tips and cutting instruments.

Advanced ceramic dental instruments offer superior edge retention and can maintain their sharpness significantly longer than metal alternatives. Their chemical inertness also makes them highly resistant to the corrosive effects of sterilization solutions and dental materials.

Coating Technologies and Surface Treatments

Diamond-Like Carbon Coatings

Diamond-like carbon (DLC) coatings represent the cutting edge in dental instrument surface treatment. These ultra-thin coatings significantly enhance the hardness and wear resistance of dental instruments while reducing friction during use. The improved surface properties lead to better performance and extended service life.

Instruments treated with DLC coatings show remarkable resistance to chemical attack and maintain their aesthetic appearance even after numerous sterilization cycles. The reduced friction also contributes to improved patient comfort during procedures.

Titanium Nitride Applications

Titanium nitride (TiN) coatings offer another sophisticated solution for enhancing dental instrument durability. This golden-colored coating not only provides superior hardness but also creates a smooth, low-friction surface that resists adhesion of dental materials.

The application of TiN coatings can extend the life of dental instruments by up to three times compared to uncoated instruments. The distinctive gold color also aids in quick identification and sorting of instruments in busy clinical settings.

Maintenance Considerations for Different Materials

Cleaning and Sterilization Protocols

Different materials require specific care protocols to maintain their optimal performance. Stainless steel instruments benefit from immediate cleaning after use and proper drying to prevent corrosion. Composite materials may require gentler cleaning agents to preserve their surface integrity.

Understanding the appropriate sterilization temperatures and chemical compatibilities for each material type is crucial for maintaining the longevity of dental instruments. Regular inspection for signs of wear or damage helps ensure consistent performance and patient safety.

Storage and Handling Best Practices

Proper storage conditions play a vital role in preserving dental instruments regardless of their material composition. Maintaining appropriate humidity levels and using instrument cassettes can prevent unnecessary wear and damage. Regular maintenance schedules, including professional sharpening and refurbishment, help extend the service life of premium instruments.

Training staff in proper handling techniques specific to different materials ensures that investments in high-quality dental instruments pay off through extended service life and reliable performance.

Frequently Asked Questions

How often should dental instruments be replaced?

The replacement frequency depends on the material quality, usage intensity, and maintenance practices. High-quality stainless steel and titanium instruments can last 5-10 years with proper care, while composite instruments typically require replacement every 3-5 years. Regular inspection and professional assessment help determine optimal replacement timing.

What makes surgical-grade stainless steel different from regular stainless steel?

Surgical-grade stainless steel contains specific alloy compositions that provide enhanced corrosion resistance, superior strength, and better edge retention. It undergoes stringent quality control processes and must meet strict medical device standards for biocompatibility and performance.

Are titanium dental instruments worth the higher investment?

For practitioners performing precise or lengthy procedures, titanium instruments often justify their higher cost through reduced hand fatigue, excellent durability, and superior tactile feedback. The material's lightweight nature and corrosion resistance make it particularly valuable for microsurgical applications and specialized procedures.