Professional precision work demands tools that deliver exceptional accuracy while maintaining the highest safety standards. Whether you're working in dental laboratories, jewelry manufacturing, or intricate mechanical applications, the choice of filing instruments can significantly impact both the quality of your results and workplace safety. Understanding proper tool selection, handling techniques, and maintenance protocols ensures that your precision filing operations meet industry standards while protecting both operators and workpieces.

Understanding Precision Filing Requirements

Material Compatibility and Selection Criteria

The foundation of safe and precise filing begins with understanding material compatibility between your filing tools and target materials. Different metals, composites, and synthetic materials require specific file characteristics to achieve optimal results without compromising safety. Tungsten steel filing implements offer superior hardness and durability, making them ideal for applications involving precious metals, dental materials, and precision components that demand exceptional surface finishes.

When selecting filing tools, consider the material hardness differential between your implement and workpiece. The file should be significantly harder than the target material to ensure effective material removal while maintaining tool integrity throughout extended use. This hardness differential prevents premature tool wear and reduces the risk of file breakage, which can create dangerous metal fragments in the workspace.

Surface preparation requirements also influence tool selection decisions. Fine-grit needle files excel in applications requiring smooth surface finishes, while coarser variants handle rapid material removal tasks more efficiently. Understanding these distinctions helps prevent excessive force application, reducing operator fatigue and minimizing the risk of slip-related accidents that can occur when inappropriate tools are used for specific tasks.

Workspace Setup and Environmental Considerations

Creating a controlled filing environment significantly enhances both safety and precision outcomes. Proper lighting, ventilation, and surface preparation establish the foundation for successful precision filing operations. Adequate illumination prevents eye strain and enables accurate visual assessment of filing progress, while proper ventilation systems remove metal particles and debris that could otherwise create respiratory hazards.

Work surface stability directly impacts filing precision and operator safety. Rigid mounting systems or specialized vises secure workpieces firmly, preventing movement that could cause tool slippage or dimensional inaccuracies. Anti-vibration materials beneath workstations further enhance stability, particularly important when working with delicate components where minor vibrations can affect surface finish quality.

Temperature control considerations become critical in precision applications where thermal expansion could affect dimensional accuracy. Maintaining consistent ambient temperatures and allowing tools and workpieces to reach thermal equilibrium prevents expansion-related dimensional variations that could compromise final product specifications. This environmental control proves especially important in dental applications where precise fits are essential.

Safety Protocols and Risk Management

Personal Protective Equipment Requirements

Comprehensive personal protection forms the cornerstone of safe filing operations. Eye protection shields against metal particles and debris that inevitably result from filing activities. Safety glasses or face shields should meet industry standards for impact resistance and provide adequate coverage for the specific filing applications being performed. Prescription safety glasses ensure that operators with vision correction needs maintain both protection and visual acuity.

Hand and arm protection involves multiple considerations beyond simple glove selection. Cut-resistant gloves protect against sharp edges and filing debris, while maintaining sufficient dexterity for precise manipulation. However, glove selection must balance protection with tactile sensitivity, as excessive thickness can reduce feel and potentially increase accident risk through reduced control. Some precision applications may require bare-hand work with enhanced focus on proper tool handling techniques.

Respiratory protection becomes essential when filing generates significant airborne particles, particularly with exotic materials or in enclosed workspaces. Dust masks or respirators prevent inhalation of metal particles that could cause long-term health effects. The specific protection level required depends on material types, particle generation rates, and workspace ventilation effectiveness.

Tool Handling and Ergonomic Safety

Proper grip techniques minimize hand fatigue while maximizing control precision. Needle files require lighter grip pressures than larger files, as excessive force can cause breakage or loss of control. The pencil grip method often provides optimal balance between control and comfort for detailed work, while allowing natural wrist positioning that reduces strain during extended operations.

Filing motion patterns significantly impact both safety and results quality. Smooth, consistent strokes prevent catching or binding that could cause sudden tool movement or breakage. Forward-cutting files should move primarily in one direction to maintain cutting efficiency and prevent premature dulling. Understanding the cutting action of different file types helps operators apply appropriate pressure and motion patterns for optimal performance.

Regular rest periods prevent fatigue-related accidents that commonly occur during precision work. Hand and wrist exercises between filing sessions maintain flexibility and circulation, reducing the risk of repetitive strain injuries. Recognizing early signs of fatigue, such as reduced precision or increased effort requirements, signals the need for breaks before safety becomes compromised.

Precision Techniques and Quality Control

Measurement and Progress Monitoring

Accurate measurement techniques ensure that filing operations achieve specified dimensions without over-removal that could require costly rework or component replacement. Digital calipers, micrometers, and specialized gauges provide the precision required for critical applications. Regular measurement intervals during filing prevent excessive material removal and enable correction of dimensional drift before it becomes problematic.

Visual inspection techniques complement dimensional measurements in assessing filing quality. Proper lighting angles reveal surface irregularities, scratch patterns, and finish consistency that may not be apparent under standard illumination. Magnification tools enhance visual assessment capabilities, particularly important when evaluating surface finish requirements in precision applications.

Documentation of filing progress provides valuable feedback for process improvement and quality assurance. Recording measurement data, technique variations, and results quality creates a reference database that helps refine procedures and identify optimal approaches for specific applications. This documentation proves particularly valuable in production environments where consistency across multiple operators is essential.

Surface Finish Optimization

Achieving optimal surface finishes requires understanding the relationship between file characteristics, technique parameters, and material properties. File cut patterns, grit sizes, and cutting angles all influence final surface quality. Progressive filing sequences, starting with coarser files and advancing to finer grits, produce superior finishes compared to single-grit approaches.

Cross-hatching techniques can eliminate directional scratches and create more uniform surface textures. Alternating filing directions at specific angles distributes cutting marks evenly, resulting in improved surface appearance and reduced stress concentration points that could affect component performance. The specific cross-hatch angles depend on material properties and final finish requirements.

Final finishing procedures often involve specialized compounds or secondary processes to achieve mirror-like surfaces when required. Understanding when mechanical filing should transition to polishing compounds prevents over-working surfaces while achieving specified finish requirements efficiently. These transition points vary with material types and application demands.

Maintenance and Tool Longevity

Cleaning and Storage Protocols

Proper tool maintenance significantly extends file life while maintaining cutting performance throughout their service life. Regular cleaning removes accumulated metal particles that can clog cutting surfaces and reduce efficiency. Specialized file cleaning brushes effectively remove debris without damaging delicate cutting teeth, while ultrasonic cleaning systems provide thorough cleaning for heavily contaminated tools.

Storage conditions directly impact tool longevity and performance consistency. Moisture control prevents corrosion that can damage cutting surfaces and affect dimensional accuracy. Individual tool protection, such as sheaths or designated storage slots, prevents damage from contact with other tools while maintaining organization for efficient access during work operations.

Inventory rotation systems ensure that tools receive uniform use, preventing premature wear of frequently selected implements while others remain underutilized. Regular inspection schedules identify wear patterns, damage, or degradation before these issues affect work quality or create safety hazards through unexpected tool failure.

Performance Assessment and Replacement Criteria

Systematic performance evaluation helps determine optimal replacement timing before tool degradation affects work quality or safety. Cutting efficiency tests, using standardized materials and procedures, provide objective measures of tool condition that supplement visual inspection methods. Documenting performance metrics creates replacement schedules based on actual usage rather than arbitrary time intervals.

Wear pattern analysis reveals information about usage techniques and helps identify opportunities for procedure optimization. Uneven wear patterns may indicate improper handling techniques, while premature wear could suggest inappropriate tool selection for specific applications. This analysis contributes to both improved tool life and enhanced operator training programs.

Economic replacement criteria balance tool costs against productivity and quality considerations. While extending tool life reduces direct costs, using worn tools can increase labor time, reduce work quality, and create safety risks that outweigh the savings from delayed replacement. Establishing clear replacement criteria based on performance metrics ensures optimal balance between cost control and operational efficiency.

Applications and Industry-Specific Considerations

Dental and Medical Device Manufacturing

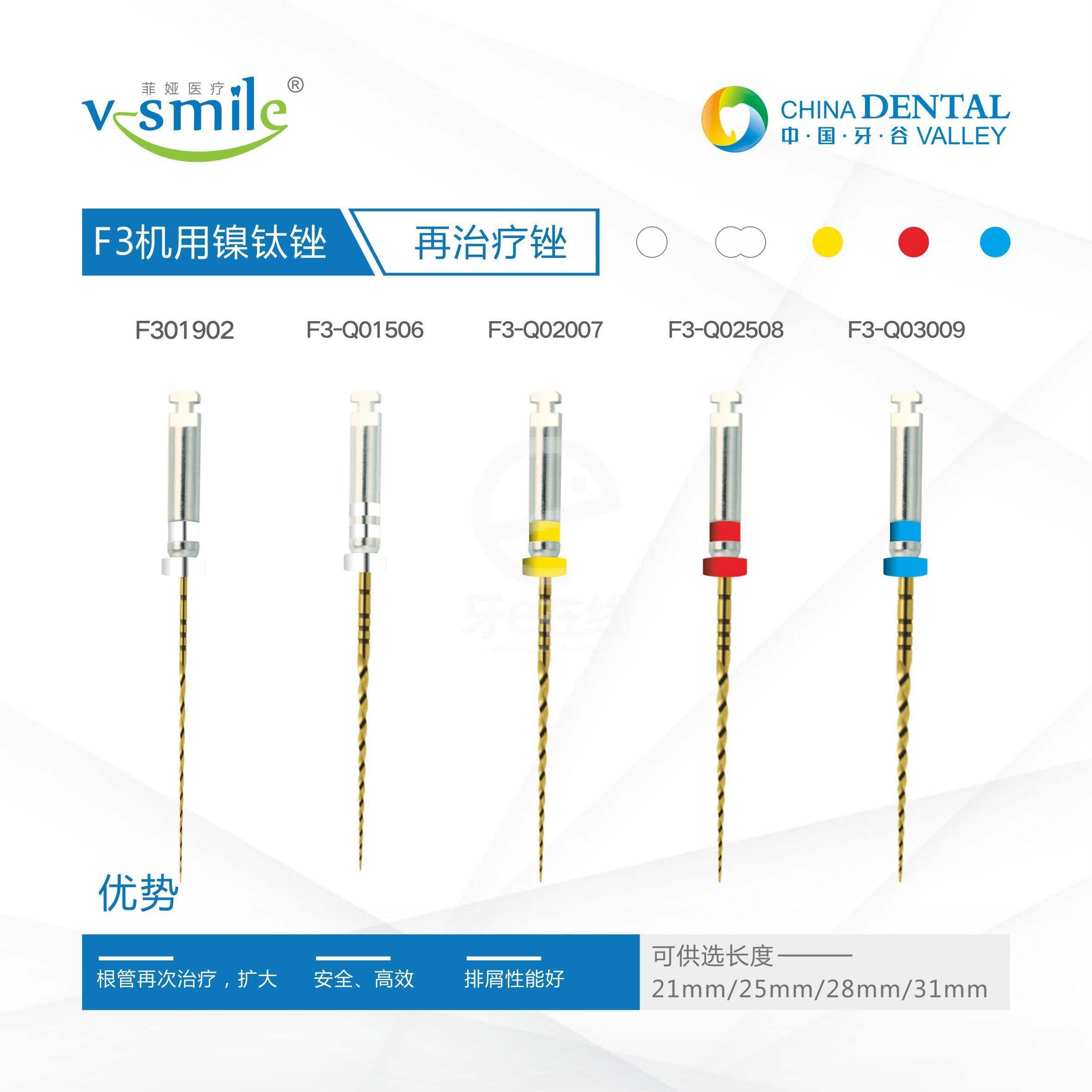

Medical applications demand exceptional precision and surface finish quality due to biocompatibility requirements and functional performance specifications. Needle files used in dental prosthetic fabrication must achieve surface finishes that prevent bacterial accumulation while maintaining dimensional accuracy for proper fit and function. The stakes are particularly high, as improper filing techniques can compromise patient safety and treatment effectiveness.

Sterilization compatibility becomes a critical factor when selecting filing tools for medical applications. Tools must withstand repeated sterilization cycles without degradation of cutting performance or dimensional stability. Tungsten steel implements typically offer superior sterilization resistance compared to conventional steel alternatives, making them preferred choices for reusable medical instruments.

Contamination prevention protocols in medical applications extend beyond standard workshop cleanliness requirements. Cross-contamination between patients or materials requires dedicated tools or thorough decontamination procedures between uses. Understanding these requirements influences tool selection, maintenance procedures, and workflow organization in medical manufacturing environments.

Jewelry and Precision Manufacturing

Jewelry manufacturing applications emphasize surface finish quality and dimensional precision, particularly when working with precious metals where material waste directly impacts profitability. Needle files enable intricate detail work that defines the quality and value of finished pieces. The ability to achieve consistent results across multiple pieces requires both skilled technique and appropriate tool selection.

Heat sensitivity considerations become important when working with materials that may be affected by filing-generated heat. Some metals and alloys can experience work hardening or thermal damage from excessive filing pressure or speed. Understanding these material characteristics helps prevent quality issues while maintaining efficient production rates.

Precision tolerances in jewelry work often exceed those found in many industrial applications, particularly for components that must fit together precisely or interface with mechanical movements. Achieving and maintaining these tolerances requires careful technique development and consistent quality control procedures throughout the filing process.

FAQ

What safety equipment is essential when using needle files

Essential safety equipment includes safety glasses or face shields to protect against metal particles, cut-resistant gloves when handling sharp workpieces, and respiratory protection when filing generates significant airborne debris. The specific protection level depends on materials being filed and workspace conditions. Ensure all protective equipment meets relevant safety standards for your application.

How can I determine when needle files need replacement

Replace needle files when cutting efficiency noticeably decreases, requiring excessive pressure to achieve material removal. Visual signs include worn or damaged cutting teeth, bent or cracked file bodies, or accumulated debris that cannot be cleaned effectively. Performance testing on standardized materials provides objective replacement criteria beyond visual inspection.

What techniques prevent workpiece damage during precision filing

Prevent workpiece damage by using appropriate clamping that distributes pressure evenly, selecting files with suitable cut patterns for the material hardness, and applying consistent light pressure rather than forcing the cutting action. Regular measurement prevents over-removal, while proper file maintenance ensures clean cutting action that minimizes surface damage.

How do I maintain consistent surface finishes across multiple components

Maintain consistent surface finishes by standardizing filing pressure, stroke patterns, and progression sequences across all components. Use the same file types and replacement criteria for similar work, document successful techniques for reference, and implement quality control checkpoints throughout the filing process. Environmental factors like lighting and workpiece positioning should remain consistent between operations.